Are you experiencing reduced heat transfer efficiency that is costing you through reduced output or increased energy cost? A range of problems can lead to poor performance or failure of your plate heat exchangers. The four most common plate heat exchanger problems that occur are:

- Fouling- leads to reduced heat transfer and potentially higher energy costs

- Blockage- leads to reduced heat transfer and potentially higher energy costs, increased fluid velocity leading to potential erosion problems

- External leakage- leads to wasted product and potentially dangerous spills

- Internal Leakage- leads to cross contamination of the fluids

- External Leakage of Plate Heat Exchanger

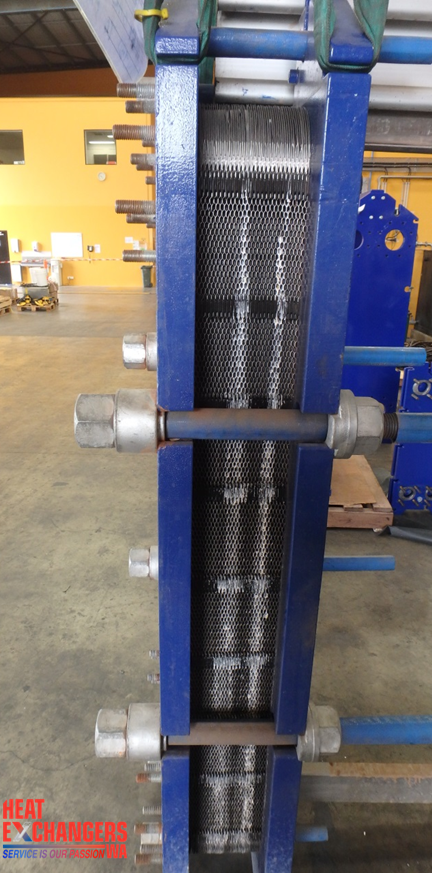

- Partial Blockage of Plate Heat Exchanger Leading to Flow Channels

- Fouled Plate Heat Exchanger

Typically, plate heat exchanger performance issues can be remedied by servicing the heat exchanger to bring it back to its original design capacity. An analysis of the plate heat exchanger should be conducted in order to assess the problem and determine its solution as quickly as possible. This is important as problems can escalate if left unattended.

Fouling deposition comes in many forms such as settlement of particulates, biological deposits, decomposition and crystallisation. Fouling is heavily dependent upon the process fluid, operating conditions and overall design of the heat exchanger. Fouling reduces the heat transfer between fluids, impedes fluid flow, increases pressure drop and impacts upon the overall efficiency of the heat exchanger and attached systems. It is crucial to determine the type of fouling and its mechanism to provide adequate mitigation strategies. Biological fouling and settlement of particulates can typically be reduced by improving filtration upstream. Other forms of fouling can be reduced at times by altering fluid velocities or upgrading the process heat exchangers to one with optimised designs and superior temperature control.

Partial blockages result in non-uniform flow over the heat exchanger plate affecting heat transfer and increasing velocities, which can result in increased erosion rates. Leakage can occur through port liners allowing fluid to come in contact with the frame plate. In this situation the frame plate can corrode resulting in a more expensive repair.

The cross-contamination of fluids occurs due to the perforation of a plate within the heat exchanger. This worst case scenario is uncommon, however, it can occur due to an aggressive chemical or long periods of operation at high temperatures/pressures. The cross-contamination of fluids will be difficult to detect as the heat exchanger will not leak externally. It is therefore important to be aware of the condition of the process fluids to detect an internal leak. Internal leakage can be minimised by the selection of the most appropriate plate material for the conditions in the heat exchanger. Perforated plates are detected during servicing or by hydrostatic or gas testing.

Heat Exchanger inefficiency or failure can be overcome by the implementation of an appropriate maintenance strategy. The cost of failure or inefficiency can be many times the cost of servicing when additional energy costs and lost productivity, particularly in the event of an unplanned shutdown of your plant are considered.

[…] more information on maintaining your heat exchanger read our other article, ‘Maintain Your Heat Exchanger to Maintain Your Bottom Line‘. Alternatively, feel free to contact us directly at Heat Exchangers WA on (08) 9350 […]