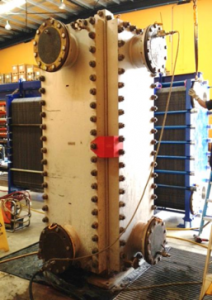

The welded (BLOC) plate heat exchangers contain more robust plates with greater thickness and do not have standard PHE rubber gaskets. This different design allows higher temperature and pressure ranges. Compact in design, they still pack a punch with outstanding heat transfer coefficients, even under the most stringent applications. Heat Exchangers WA provide servicing of welded (BLOC) plate heat exchangers, having serviced several COMPA-BLOC from mineral processing plants.

HEWA’s purpose built 4000 m2 workshop offers drive-in and out delivery with 32 & 10 tonne gantry cranes to allow easy lifting and improved service efficiency. Our trained technicians provide a range of tooling competency to remove the welded plate (BLOC) heat exchanger nuts and side panels.

After assessment of blockages, the welded core is lifted for cleaning in the 17,000 L chemical static baths and high pressure wash bay. Simultaneously, the port liners on the side panels are integrity tested via red dye and structurally repaired if required.

Following cleaning and port liner repair, the welded core is assessed before reassembling the BLOC and hydro testing. Upon completion of the service, the welded (BLOC) plate heat exchanger is dispatched and the client provided with a comprehensive report detailing the extent of the service. Heat Exchangers WA have been continuously working toward improving the efficiency with which we service BLOC’s, having reduced the required man hours by over 50%.