Heat Exchangers

Heat Exchangers WA is the only plate heat exchanger provider in WA with a purpose-built Assembly Unit for gasket plate heat exchangers. We strive for fast designs, fast supply at a competitive price without compromise to quality for your Industrial requirement.

Heat Exchangers WA are qualified to service and repair any make and model of plate heat exchanger, including but not limited to: Alfa Laval, APV, Funke, GEA, Heat Exchangers International, Hisaka, Pasillac Reheat, Schimdt, Sondex, Swep, Thermowave, Tranter, Vicarb.

HEWA supply both manufacturers’ and after-market spares, which have been independently tested and are compatible with the original manufacturer’s equipment.

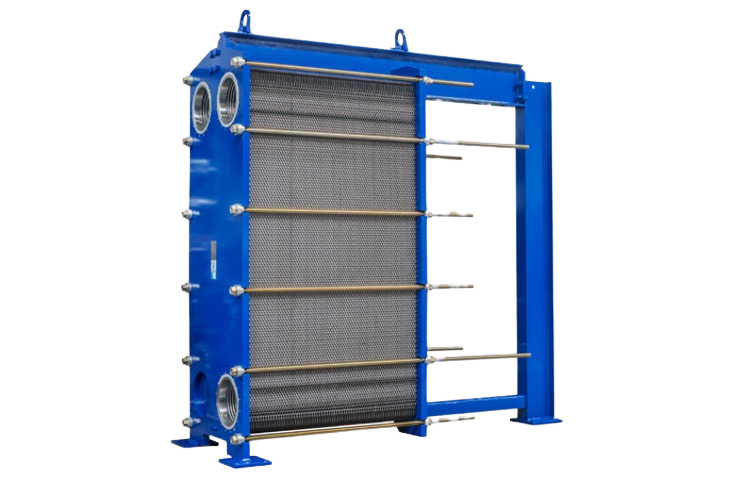

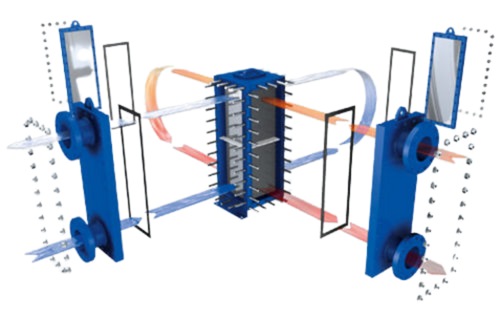

Plate and frame heat exchangers

The plate and frame heat exchanger is a compact and efficient heat transfer solution for a wide variety of applications in practically all industries.

Sealed with gaskets, the plate and frame heat exchanger works with a low pressure drop whilst maintaining high turbulence across the plate surface for maximum heat transfer.

The plate and frame heat exchanger provides easy maintenance due to its ability to be disassembled, allowing cleaning, servicing and replacement of parts if required.

Brazed Plate Heat Exchangers

The brazed plate heat exchanger is an assembled tight package of thin corrugated plates that are copper vacuum-brazed between rear and front cover-plates. Connections are mounted on the cover plates and are available in various styles and sizes depending upon client requirements. Operational advantages of brazed plate heat exchangers include:

- Compact design with greater spatial efficiency

- Suitable for higher temperatures and pressures than plate and frame heat exchangers

Welded Plate Heat Exchangers

The fully welded plate heat exchangers contain more robust plates with greater thickness, allowing suitability at higher temperature and pressure ranges. Minimal in size, they still pack a punch with outstanding heat transfer coefficients and comparatively minimal investment costs. They are particularly robust and require minimal cleaning and service. Our fully-welded plate heat exchangers offer convincing performance, even under the most difficult circumstances.

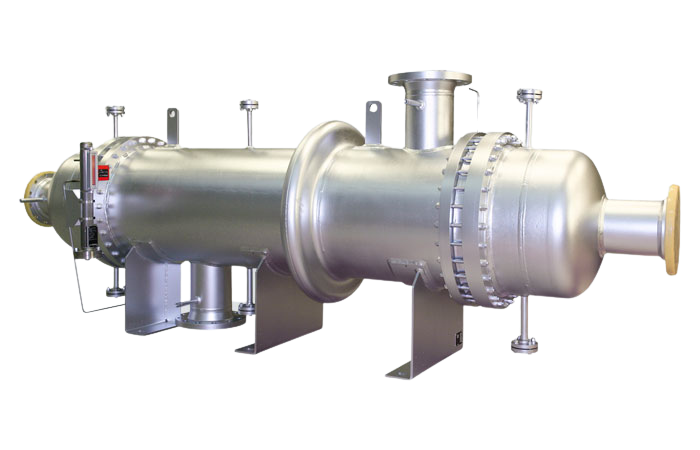

Shell And Tube Heat Exchangers

Shell & Tube heat exchangers are the most common design for many applications. We provide a wide variety of product lines based on the most suitable design and materials to ensure a cost efficient and reliable solution. The full range provides standardized product lines for an optimal price/quality ratio as well as customized designs for the most demanding duties in oil & gas, power generation, marine, refrigeration and many other industries.

More Inquiry!

LEAVE US A MESSAGE