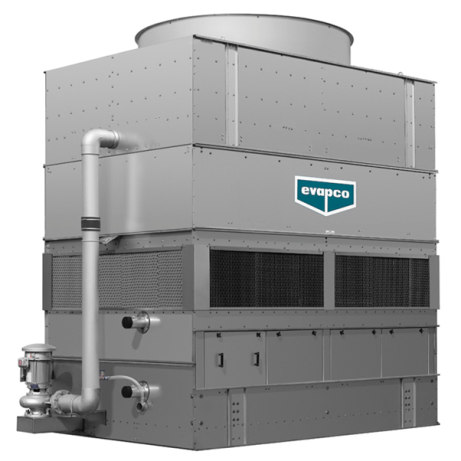

Cooling Towers

Heat Exchangers WA (HEWA) is the exclusive factory-authorised representative of Evapco in Western Australia. HEWA supplies the full range of Evapco’s cooling towers, closed circuit fluid coolers, and evaporative condensers, all designed at Evapco’s Headquarters in America. Evapco designs, manufactures and assembles all main components; for Western Australian projects, HEWA can offer local assembly (freight savings) at our purpose-built facility in Beckenham, Perth, WA.

Since its beginnings 1976, Evapco has developed into one of the world’s largest and most environmentally-conscious manufacturers of premium-quality evaporative equipment. While maintaining a global profile, the company remains employee-owned and centred on small-business values. The vast product range available in Australia offers the following advantages:

- Thermal ratings verified and certified by a third-party organisation (CTI)

- Variable materials of construction to suit any application or specification (galvanised steel, stainless steel, and fibreglass)

- Ideal combination of low energy consumption AND low sound emission

- Industry-leading warranty period backed by the manufacturer

- Much, much more!

The further advantages come from HEWA’s local knowledge and capabilities, which include sales & technical assistance, equipment assembly, troubleshooting, on-site inspections, field service, and the complete restoration of any evaporative cooling product by any manufacturer. Heat Exchangers Perth WA is a “one-stop-shop” for all of your evaporative cooling needs, please give us a call today!

Open Circuit Cooling Towers

Induced or forced draft open Circuit cooling towers are available in galvanised steel, stainless steel grades or fibreglass depending upon required corrosion resistance. Cooling towers, such as the LPT, can be designed to meet height restrictions or low noise requirements. Ease of maintenance is increased through easy basin access and belt drive system.

Air Cooled Closed Circuit Coolers

Air cooled closed circuit coolers are designed according to the customers’ requirements and assure exact compliance with their performance specifications. Our finned systems enhance heat exchange to the tube system and allow low material usage without performance loss. Tooling flexibility allows each system to be adjusted with its tube banks side by side or on top of each other, allowing us to meet extreme customer demands. Our many official approvals and certifications allow us to design and manufacture closed circuit coolers for a large variety of applications.

Advantages:

- Tube systems with enhanced heat transfer

- Different materials and surface protection for gas side cooling surface

- High corrosion resistant tube material (stainless steel, titanium etc.)

- Safe operation with double tube system.

Evaporative Closed Circuit Coolers

Induced or forced draft closed circuit coolers ensure that process fluid is not exposed to the atmosphere, eliminating exposure to oxygen and other impurities. Construction materials are available in high quality galvanised or stainless steels.

Air Cooled Condensers

Our extensive Kelvion product range includes customised condensers (Goedhart), commercial condensers (Kuba) and even industrial condensers (Searle). We provide process optimised model ranges that are unique in their number and specifications.

More Inquiry!

LEAVE US A MESSAGE